Value Addition to Millets - Juniper publishers

Journal of Trends in Technical and Scientific Research

Opinion

Indian Institute of Millets Research (IIMR) has

pioneered in diversification of processing technologies in millet in

order to provide wide options to consumers, otherwise prior to IIMR

initiative due to absence of the convenient technologies in millets led

to decline in their consumption. Developed millets value added Ready to

Cook/Ready to Eat products, now value added technologies are made

available for wider consumption to meet the consumer requirements

(healthy and tasty).

Description of Technology

Millets are neither ready to eat nor ready to cook

grains and need some kind of processing invariably for human

consumption. Most commonly followed conventional processing

methodologies are milling including decortication and size gradation,

popping, malting, and fermentation. In the recent years the contemporary

food processing technologies such as extrusion cooking, cold extrusion

(vermicelli/ pasta/noodles), baking, flaking and, puffing are applied

for millets (Figure 1).

Primary processing

It is the processing to clean the grain through grading

(depend on size of the grain), de-stoning (removal of stones)

and de-hulling (polishing). The bulk operations of these

processes can be done mechanically. Primary processing of the

grain is removal of waste, stones and glumes from the grain

that are necessary as it improves the storage of the grain.

Secondary processing

It involves use of the primary processed raw material in

to different ready to cook sorghum products such as flour and

semolina or suji (fine and medium), sorghum based multigrain

flour, extruded products (vermicelli and pasta) and parboiled

sorghum and ready to eat (biscuits, flakes, pops and multigrain

roti) (Figure 2) .

Interventions

a. Standardized primary processing of millets

b. Enhanced shelf life

c. Identified cultivars suitable for specific products

d. Nutrition profiling done

e. Established nutritional superiority over existing rice/

wheat based products

f. Machines are developed and standardized to processing

millets

g. Backward integrator model established in collaboration

with ITC (ABD)

h. Farm gate processing helped in value addition to

farmers

Commercialization

IIMR has developed 40 technologies of which 22 millet

products are commercialized under the brand of “eatrite”

solely to increase the consumption of millet in the country.

Processing technologies were licensed by IIMR to 40 private

companies some of them have established millet processing

units in different states Telangana (8), Andhra Pradesh,

Maharashtra (2), Tamilnadu (2), Karnataka (1), and New Delhi

(3) to manufacture and promote sorghum and millet value

added products to reach millet products to consumers. Multi

National Company M/s Britannia Industries Ltd. signed MoU

with IIMR to work jointly on R&D of millet bakery products

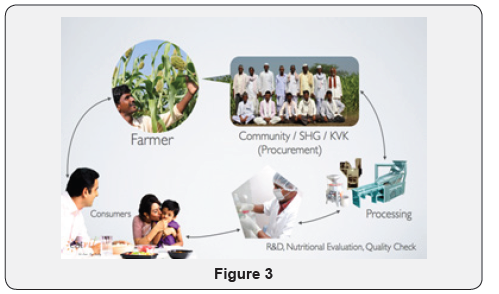

(biscuits) to include millets in nutri-choice (Figure 3&4).

Impact

Value addition to the millets impact on different aspects

primarily it creates demand and usage of millets in the

consumer’s daily diet in present lifestyle. Millets have good

health benefits to prevent diabetes, cardiovascular disease,

blood pressure, cancer etc. entrepreneurs come forward to

start the millet processing units for this they required raw

material so ultimately its impact on farmers to cultivate millets

to meet the demand for processing and consumption of millets.

On technological intervention has been successful in creating

options for consumers in millets. This has led to impact both

consumers whoever suffering from life style diseases as

healthy choice but also to enhance the farmer’s income.

To Know More About Trends in Technical and ScientificResearch click on: https://juniperpublishers.com/ttsr/index.php

To Know More About Open Access Journals Please click on:

Comments

Post a Comment