Effect of Operational Conditions on Performance of Deep Sand Filter in Turbidity Removal - Juniper publishers

Journal of Trends in Technical and Scientific Research

Abstract

In this study, laboratory pilot plant was constructed

to study the performance of deep sand filter in water treatment. Sand

was used as a filtration media under different filtration rates ranged

from 4 m/hr to 8 m/hr. Down flow was applied to the filter through sand

media with size of 0.7-1.0 mm, while sand depth was changed from 80 cm

to 140 cm. The used synthetic turbid water was prepared in different

turbidity levels varying from 10 to 30 NTU. Aluminum sulfate (alum) was

used as coagulant in different doses varied from 20 to 40 mg/l.

Turbidity removal and head loss were investigated as functions of sand

depth, filtration rate, alum dose and influent turbidity. From analysis

of the experimental results, it was found that the changing of

operational conditions (changing media depth, filtration rate, alum dose

and influent turbidity) have significant impact on the turbidity

removal efficiency, head loss and ripening period. Also, the effective

depth of media is influenced by operational conditions and its value was

obtained in this paper.

Keywords: Deep sand filter; Effective depth; Filtration rate; Head loss; Turbidity removal

Introduction

With an exponentially increasing of population,

better and more economical water treatment methods and strategies have

become the need of the hour. One such sustainable water treatment method

is using deep bed filters which has great potential for treating of

contaminants in drinking water [1-3].

Deep bed filtration is an effective process in

removing particles from water. This is achieved by passing the

suspension through a deep layer (usually between 0.5 m and 2.0 m depth)

of granular material, typically sand. The suspension particles are

retained within the depth of the filter media. This removal may be

achieved by different mechanisms [4-6].

In filtration process, there are different stages,

ripening, working, and breakthrough stage [7]. The removal efficiency

during ripening stage increases, while this efficiency is nearly

constant during working stage. Then the removal starts to deteriorate in

breakthrough stage [8]. During ripening period, the effluent turbidity

is relatively high. It takes some minutes to be allowable [9]. The

effluent water during this period is mostly wasted thus this period has

significant effect on the quantity of water. This period has been

studied in many researches [10-13], but the effect of different

operational conditions on this period was not clear. So, this paper will

study that effect.

Numerous empirical equations, which are used to

predict initial filter head loss, have been developed. Some commonly

used equations are Carmen-Kozeny, Ergun, Fair-Hatch, Hazen, Rose, and

Gregory equations [14,15]. These equations may be unacceptable for

specific types of media such as crumb rubber. it was found that Both the

Kozeny and Ergun equations were unacceptable for clean-bed head loss

prediction in crumb rubber filters [16]. A neuro-fuzzy model was

conducted to estimate head loss in dirty sand filters. Hydraulic loading

rate, influent iron concentration, bed porosity, and operating time

were selected as input variables [17].

Many researchers studied the deep bed filter and its

performance. One of these studies showed that the removal efficiency

during the ripening stage of filtration can be improved significantly by

increasing the ionic strength of the water to be treated [18]. In

addition, the structure of porous media (i.e., pore size distribution)

has a clear effect on deep bed filter performance [19]. Moreover, impact

of backwash procedures on deep bed filtration productivity in drinking

water was presented [20]. From modeling point of view, many models were

introduced to explain the efficiency and performance of deep bed

filters, [21-25].

Through deep bed filters, not all used media depth is

effective in turbidity removal but there is an effective depth which

give the required or permissible limit. The effective depth for media

from burned oil palm shell granular has been obtained [26]. Moreover,

knowing the effective depth of turbidity removal will assist in

identifying depth of the sand during filter design.

Using granular sand filters has a limitation of

influent quality. When it used with drastic influent quality with small

depth it don’t give the required quality. Therefore,

another technique is required such as using deeper filter. The

main objectives of this study is to investigate the effect of

operational conditions on the performance of deep sand filter

and to determine the effective depth for turbidity removal.

Materials and Methods

For this study, a Laboratory pilot plant was designed and

constructed in the laboratory of sanitary engineering in the

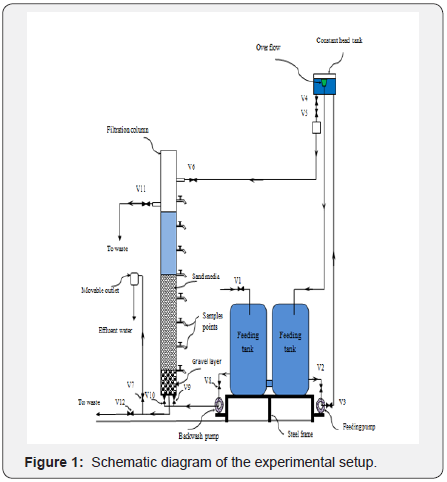

faculty of engineering – El- Mansoura University, Egypt. Figure

1 shows the schematic diagram of the laboratory pilot plant.

Experimental set up description

It consisted of the following main parts: -

a. Feeding tanks: The synthetic turbid (raw) water

was prepared in four plastic feeding tanks. The four tanks

divided into two groups each group consist of two tanks.

The capacity of each tank was about 250 liters.

b. Feeding pump: The synthetic turbid water was

transported from feeding tanks to a constant head tank

by feeding pump. The horsepower of pump were 0.45 HP

(Discharge 0.45 m3/hr).

c. Constant head tank: The raw water has been fed

from the feeding tanks to the sand filter via a constant head

tank. The capacity of constant head tank was 45 liters and

has dimensions of 30 * 30 * 50 cm. Constant head tank has

confirmed a constant discharge to the plant whatever the

difference in water levels before and after it.

d. Filtration column: The major part of the laboratory

pilot plant was the filtration column. The filtration column was made from galvanized steel with height 2.5 meters.

The column consists of two parts each part 1.25 m height

and it has square cross section (20 *20 cm). The filtration

column has one glass face to allow monitoring what is inside

the column. Along the filtration column several connection

points were fixed each 20 cm as samples ports.

e. Backwash Pumps: Two pumps were used for

backwashing. The horsepower of each pump were 0.45 HP

(Discharge of each pump 0.45 m3/hr).

f. Piezometers: Manometer tubes installed behind

filtration column to determine the head loss through the

filtration media depth at different times.

g. Fittings and Plastic connecting pipes: There were

different service connections such as elbow, tee, reducer

and connecting pipes with different diameters due to its

location and use.

Filter media

In this study, the filtration media was uniform sand media

rested on the gravel layer. The sand depth in the filtration

column was changed from 80cm to 140cm with size of 0.7-

1.0mm and its porosity was 0.38. The dry density of the sand

was 1.65 gm/cm3 and its specific gravity was 2.55. The gravel

depth under the sand was about 20cm with different sizes

ranged from 2.0mm to 9.0mm. The gravel layer is located

immediately below the filter sand media to separate the filter

media from the underdrain system, to prevent media particles

from clogging the underdrain orifice, and to dissipate the

backwash water jets from the orifice of the underdrain system

[27,28].

Synthetic raw water

By using fine clay soil and tap water it was able to achieve

the synthetic raw water which can be used in the experimental

work. The raw water was prepared by dispersing fine clay,

having a size less than 0.074mm, in tap water. In this research,

the synthetic raw water turbidity was ranged up to 30 NTU

which is a suitable range in the River Nile and its branches in

Egypt.

Laboratory pilot plant operation

This study has been extended to cover the various operation

conditions for the sand bed filter. In present research, different

positions for Aluminum sulfate (alum) feeding were tested as

a coagulation process. it was found that feeding alum dose in

feeding tanks gives high filtration efficiency with doses varied

from 20 to 40mg/l. The operation of the laboratory pilot plant

was controlled by 12 valves (shown in Figure 1). These valves

facilitate two modes of filter operation (down flow filtration

mode and filter backwash mode).

a. Filtration mode: The experimental runs were

conducted under the conditions of a direct constant filtration rate. The operated filtration rate was changed

from 4m/hr to 8m/hr (suitable for rapid sand filter). The

effluent turbidity was measured at different depths each

1 minute for the first 30 minutes (to assess the ripening

period) then it was measured each one hour throughout

the remaining part of the run. The turbidity of influent

and effluent water was measured by using turbidimeter in

Nephelometric Turbidity Unit (NTU). Its model is Orbeco

TB300-IR Lab Turbidimeter. In addition, the head loss

through sand media was measured by Piezometers each

one hour. The effluent turbidity measurements at different

depths will help in determining of effective sand depth and

developing of simplified model for filter efficiency.

b. Backwash mode: The end of filtration run was

considered when effluent turbidity started to increase

(turbidity breakthrough) or head loss reaches the

maximum value or the run length reaches defined period

(in this research, one day). Once either of this condition

was reached, the filter run was terminated and the filter

needs to backwash mode to remove the accumulated solids

inside its bed [29,15]. Water only with high rate (50m/hr)

was used as a backwash method [30]. The backwash period

was extended to 18minutes and during this period, the

wasted backwash water turbidity was measured each 1

minute to appraise the required backwash duration.

Various runs were conducted under different operational

conditions (varying the media depth, filtration rate, influent

turbidity and alum dose) to study the performance and get the

effective depth for deep bed sand filter.

Results and Discussions

Ripening period

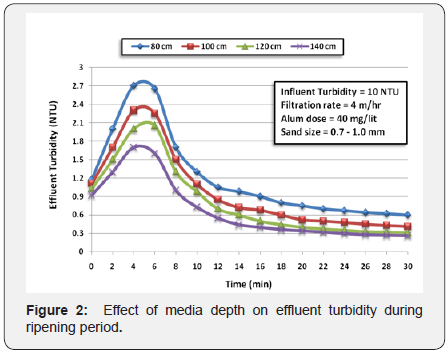

In this study, the effluent turbidity within the first 30

minutes was measured at each of tested filtration rates (4, 5,

6, and 8m/hr) and through the different media depths (80, 100,

120, and 140cm). The results were obtained with 3 different

influent turbidity (10, 20, and 30 NTU). The coagulation

process was done by using alum with different doses (20,

30, and 40mg/l). the effluent turbidity was observed until it

reaches the acceptable limit in the Egyptian drinking water

code (1 NTU) to obtain the ripening period. Figure 2 shows the

effect of increasing media depth on the ripening period for 10

NTU influent turbidity and alum dose of 40mg/l. As shown in

that figure, the effluent turbidity in the beginning of filtration

run was nearly 1 NTU and this turbidity was due to the

remaining backwash water in the underdrainage system. The

turbidity increases over few period of time nearly 4minutes.

This increase was due to not removed particles that were

dislodged from the media during backwash [10]. At nearly 4 to

5 minutes the effluent turbidity reaches its maximum values

and these values vary according to the filter media depth. The

reason for increasing turbidity to this degree is that influent water enters the filter and mixes with the backwash remnant

water in the upper region of the filter. This is consistent with

the results in paper for Colton et al. [31] which showed that

the collapse pulsing duration was 4minutes. Then the effluent

turbidity decreases until it nearly becomes constant where the

media is able to capture newly influent particles [32].

From Figure 2, it was obvious that the effluent turbidity

reaches 1 NTU after 12minutes when the sand media depth

was 80cm. If the sand media increased to 140cm, the ripening

period will be virtually 7 minutes. This means that increasing

sand depth from 80cm to 140cm reduced the ripening period

by 42%. So, it help in increasing of water treatment plant

production. The effluent turbidity was influenced by increasing

filtration rate as shown in Figure 3. When the filtration rate

increased to 5m/hr the required ripening period increased.

At sand depth of 140cm the required ripening period was

10minutes, while depth of 80cm gives the required turbidity

after 32minutes. In addition, the ripening period in case of

100cm depth was 18minutes but in case of 120cm depth the

ripening period becomes 13minutes. Increasing filtration

rates may result in an inability to use a small depths as shown

in F igure 3 . A t f iltration r ate o f 6m/hr t he e ffluent t urbidity

reaches the acceptable limit after nearly 18, 25 and 40minutes

with sand depths of 140, 120 and 100cm respectively. But

depth of 80cm can’t be used due to its ripening period. This is

due to increasing filtration rates resulted in greater shearing

actions within the media pores, which enhanced the transport

of deposited turbidity matters through the filter bed. With

increasing filtration rate to 8m/hr, media depth of 100cm

can’t give acceptable effluent turbidity. Figure 3 summarizes

the required ripening period for each sand depth at different

filtration rates. Also, this figure shows that the influent

turbidity has significant effect on the ripening period. Figure

3 show great effect of operational conditions on ripening

periods, so it could be guided in determining either ripening

periods thus the productivity of treatment plant or required

media depth at different filtration rates and influent turbidity.

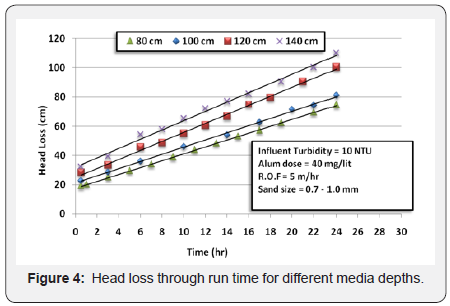

Head loss through filter run

Head loss is a loss of pressure (also known as head) by water

flowing through the filter media. In the current study, the head

loss through filter media depth was measured for different

filtration rates and various influent turbidity with alum doses

20, 30, and 40mg/l. Figure 4 shows the variation of head loss

along run time at filtration rate of 5m/hr and alum dose of

40mg/l for different depths of sand media. It was noticed that

the observed head loss values were close to the calculated head

loss from Hazen equation and Kozeny equation for sand depth

from 80cm to 140cm. It was noted from the experimental

observations that the alum dose variation has not vital effect

on the initial head loss at the same depth and filtration rate.

but it has significant effect on the increasing rate of head loss

with run time. Further, increasing filtration rate increases the

increasing rate of head loss. From Figure 4, the head loss value

after 24hours of run was nearly 110cm at sand depth of 140cm

and filtration rate of 5m/hr. This means that using deep sand

filter up to 140cm have not a critical impact on head loss value.

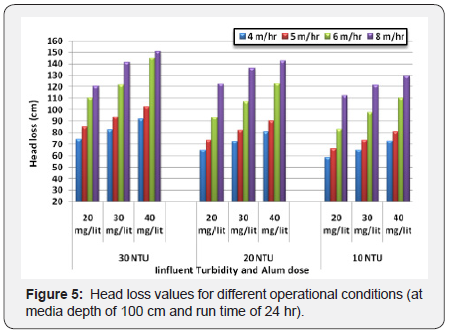

Figure 5 shows the observed head loss at specific time (24

hr) for sand depth of 100cm at different filtration rates. It also

shows the effect of changing alum dose and influent turbidity on head loss values. It was noticed that the head loss increased

from 58.7 cm to 72.9cm by increasing alum dose from 20mg/l

to 40mg/l at filtration rate and influent turbidity of 4m/hr

and 10 NTU respectively after 24hours of run. In addition, at

filtration rate 8m/hr, increasing alum dose from 20mg/l to

40mg/l increased the head loss from 112.4cm to 129.5cm.

Thus, the effect of increasing alum dose on head loss at high

rates is more obvious than low rates. Figure 5 shows also the

impact of raw water characteristics which represented in

influent turbidity on head loss. It was noted that increasing

influent turbidity from 10 NTU to 30 NTU increased head loss

from 81cm to 102.5cm at filtration rate of 5m/hr and alum

dose of 40mg/l. This is due that raw water with high turbidity

which contains larger number of suspended particles leads to

increasing of shear action when flowing through sand grains.

This shear action increases with increasing filtration rate so

the effect of influent turbidity on head loss at high rates is more

significant than at low rates as shown in Figure 5.

Turbidity removal efficiency and effective depth

Deep bed sand filter is usually characterized by filtration

efficiency, which determines the level of removal of particles

from influent water. The turbidity removal efficiency was

measured in the present study under various operational

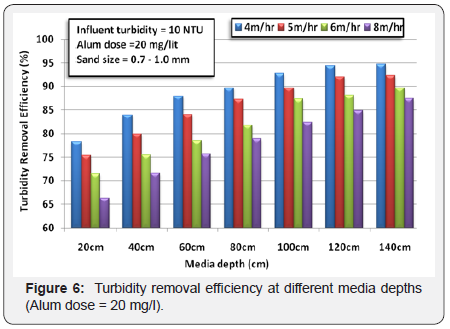

conditions. Figure 6 shows the turbidity removal efficiency

with depth at different rates. The removal efficiency was

measured as the following equation:

Figure 6 shows the removal efficiency with alum dose

20 mg/l through different sand depths at 4, 5, 6 and 8m/

hr filtration rates. It was clear that increasing media depth

increases the removal efficiency where at 20cm depth the

removal ratio was 78.4% while at 140 cm depth the ratio of

removal increased to 94.7%.

Increasing filtration rate decreases the turbidity removal

efficiency, where at 20cm depth, the removal percents for 4, 5,

6 and 8m/hr were 78.4, 75.35, 71.43 and 66.3% respectively. If

the depth of media equals 140cm, the removal percents will be

94.7, 92.36, 89.72 and 87.41% at the previous rates respectively.

It was also noticed that sand depths less than 100 cm have

drastic variation in turbidity removal efficiency, while depths

more than 100cm have slightly variation in removal efficiency

at low filtration rates.

Increasing alum dose from 20mg/l to 40mg/l has significant

impact on the percent of removal. Figure 7 show the removal

efficiency at alum dose 40mg/l with different sand depths at

4, 5, 6 and 8m/hr filtration rates. This figure also confirms

that the efficiency of removal increased by increasing sand

depth and decreasing filtration rate. The removal efficiency at

20cm depth was 78.4% with alum dose of 20mg/l but 82.7%

with alum dose 40mg/l. In case of depth 140cm, the efficiency

was 94.7% with alum dose 20mg/l but 97.9% with alum dose

of 40mg/l. This means that increasing alum dose enhanced

the coagulation process so it increases the percent of removal,

but it occurs at a certain limit of alum. After this limit, any

increasing of dose has no effect.

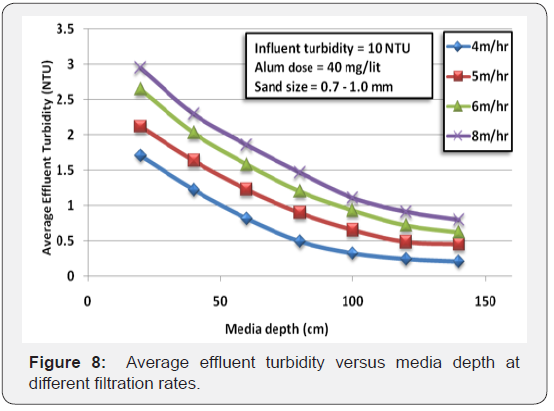

After knowing turbidity values at different depths with

various rates and various influent turbidity, effective depth of sand could be determined. The effective depth is the smallest

sand depth which give the allowable limit of turbidity (>1 NTU). The effective depth is determined as shown in Figure 8

as following:

1. Plotting the average turbidity at different depths for

each filtration rate.

2. Identify the permissible or required limit of effluent

turbidity (1 NTU).

3. The intersection points at each rate could give the

effective depth.

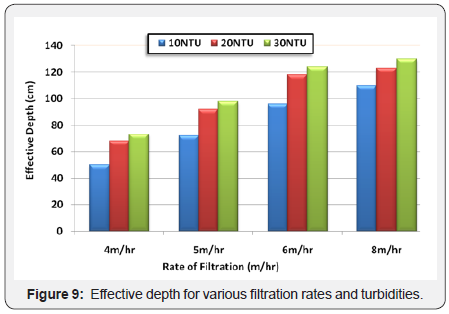

Figure 9 summarizes the effective depth for each rate with

influent turbidity 10, 20, and 30 NTU. The results in the figure

were obtained when the alum dose was 40mg/l, which gives

high removal efficiency.

From Figure 9, it was observed that sand depth of 50cm was

more suitable for filtration rate 4m/hr and influent turbidity

10 NTU. To increase the filtration rate to 8m/hr, it was needed

to increase the sand depth to 110 cm. For influent turbidity

30 NTU, 73 cm depth was suitable for 4m/hr filtration rate

whereas 130 cm depth was suitable for 8m/hr filtration rate.

Moreover, at filtration rate 8m/hr and influent turbidity less

than 30 NTU, 130 cm sand depth is sufficient to give acceptable limit of effluent turbidity. From these results, in order to

double the filtration rate nearly 60 cm of sand should be added

to the existing depth. Since the filtration rate commensurate

inversely with filter area so the filter area could be reduced by

increasing sand media depth.

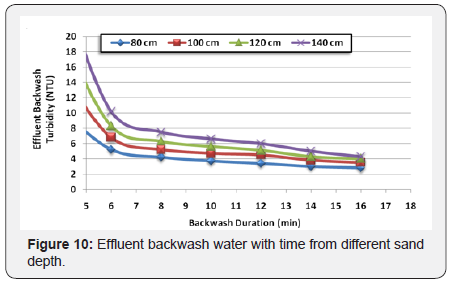

Backwash period

In the current study, backwash rate of 50m/hr was

used, which expands the media 20 percent. This rate was in

recommended range by AWWA [30]. The backwash period

extended to 16minutes until the effluent backwash water

turbidity became acceptable. The effluent turbidity during

backwash was measured and plotted as shown in Figure 10.

The wasted effluent turbidity was very high during the first

two minutes. It exceeds 700 NTU then it begins to come down

to reach 10 NTU in average after 6 minutes. From 6 minutes to

the end of backwash period, there is slight decrease in effluent

backwash turbidity. Changing sand media depth from 80 cm to

140 cm has small effect on the backwash period and duration

of 15 min is sufficient for backwashing whatever the depth of

media, as shown in Figure 10.

The value of required backwash duration was close to

reported value in previous studies [33,34]. During backwash

mode, Turbidity (4-5 NTU) was left in the backwash stream

at cutoff to preserve the bed ripening and allow the filter to

produce quality effluent more quickly for the followed run as it

was recommended by Pizze [35].

Conclusion

From experimental results, it was noted that, Changing

operational conditions (increasing media depth, filtration

rate, influent turbidity, and alum dose) have significant impact

on ripening period of filter, head loss, and turbidity removal

efficiency. This study also shows the effective depth for

different rates and it was proportional with influent turbidity

and filtration rate directly. The effective depth could be changed

by changing the nature of influent water and sand media size.

From the head loss results, it was noted that increasing rate

of head loss is influenced by alum dose, filtration rate and

influent turbidity. Moreover, using deeper sand filter helps in treatment of high turbidity water under high filtration rate and

it can reduce the area of filters.

To Know More About Trends in Technical and ScientificResearch click on: https://juniperpublishers.com/ttsr/index.php

To Know More About Open Access Journals Please click on:

Comments

Post a Comment